Good Brass for 223 Rem: Mastering Reloading Precision

Reloading .223 Remington ammunition demands meticulous brass selection. The foundation of exceptional ammunition lies in understanding what constitutes good brass, recognizing quality indicators, and implementing strategic selection techniques. This comprehensive guide will equip both novice and experienced reloaders with critical insights into selecting superior .223 Remington brass.

Understanding 223 Rem vs 5.56 Brass: Key Differences

Before selecting brass for reloading, it’s crucial to understand the difference between 223 and 556 brass. While similar in appearance, 5.56 NATO brass typically features:

- Thicker case walls

- Different pressure ratings

- Military primer crimps

- More robust construction

This makes 5.56 brass an excellent choice for reloading, though it requires additional preparation compared to commercial .223 Remington brass.

Popular Brass Options for 223/5.56 Reloading

- Starline Brass: Known for exceptional quality and consistency

- Norma Brass: Premium European manufacturer

- Winchester Brass: Reliable commercial option

- Once-fired Military 5.56: Cost-effective with proper processing

- Bulk 223 Brass: Available new or once-fired for volume reloaders

Understanding 223 Rem Brass Fundamentals

Brass serves as more than a simple cartridge container—it’s a sophisticated, precision-engineered component critical to ammunition performance. Quality brass influences accuracy, consistency, and overall shooting experience. For 223 Rem enthusiasts, understanding ballistic performance becomes paramount in achieving repeatable, high-performance results.

Key .223 Remington Brass Quality Indicators

Exceptional .223 Remington brass distinguishes itself through several critical attributes:

- Wall Thickness Consistency: Uniform case walls within 0.001-0.002 inches ensure balanced pressure distribution and improved accuracy.

- Neck Concentricity: Precise neck alignment prevents bullet wobble and enhances long-range precision.

- Primer Pocket Uniformity: Consistent primer pockets guarantee reliable ignition and minimize potential misfires.

- Material Composition: Brass alloy composition containing 70% copper and 30% zinc provides optimal elasticity and durability.

- Defect-Free Cases: Look for brass free of dents, cracks, or corrosion. Even minor flaws can impact reliability.

Top Brass Brands for 223 Rem Reloading

Not all brass is created equal. Premium manufacturers invest extensive resources in producing consistently superior cases. Here are industry-leading brands recognized for exceptional .223 Remington brass:

| Brand | Price Range | Typical Reloads | Notable Features |

|---|---|---|---|

| Federal Premium | High | 6-8 | Stringent QC, match-grade precision |

| Hornady | Medium-High | 5-7 | Advanced manufacturing techniques |

| Lapua | Premium | 8-10 | Extreme precision, competition-grade |

| Nosler | High | 6-8 | Tight manufacturing tolerances |

| Winchester | Medium | 4-6 | Reliable, cost-effective option |

223 Brass for Sale: Choosing Quality

223 Once Fired Brass vs 223 New Brass Options

- Bulk 223 brass (new and once-fired)

- 5.56 once fired brass considerations

- Processed 223 brass benefits

- Cost comparison of brass options

Essential Reloading Equipment

Basic Setup Requirements

- Digital reloading scale for precision

- Reloading powder dispenser

- 223 reloading dies (sizing and seating)

- 5.56 reloading kit options

Powder Selection Guide

- Best powder for reloading 556x45

- 223 powder for reloading options

- Barnes reloading data references

- Hornady 223 reloading data

Understanding Brass Types

.223 vs 5.56 Differences

- Case wall thickness variations

- Pressure ratings explained

- Primer pocket specifications

- Brass coated casing considerations

Bulk Purchasing Options

- 223 brass for sale sources

- Bulk reloading brass economics

- 5 gallon bucket of 223 brass

- Cost to reload 223 analysis

Advanced Reloading Topics

Specialty Ammunition

- 223 green tip loading data

- 62 grain 5.56 bullets

- Match-grade brass selection

- 223 WSSM brass considerations

Processing Methods

- Cleaning ammo brass

- Processing 223 brass steps

- Primer pocket preparation

- Case trimming requirements

Apex Ordnance Supplies The Best Brass For 223 Remington Reloading

Apex Ordnance supplies the best brass for 223 Remington reloading. Our brass is manufactured to the highest standards and is designed to meet the specific needs of tactical training and specialized shooting scenarios.

-

11 % OFF

11 % OFFHornady 223 Rem Brass 50 Rounds

Hornady's brass cases offers re-loaders excellent uniformity in wall thickness, weight and internal capacity.

$28.34 $31.98View DetailsIn Stock

-

Nosler 223 Rem Brass 100 Rounds

Made in the USA, Nosler custom brass is weight sorted for maximum accuracy and consistency potential.

$86.24View DetailsIn Stock

-

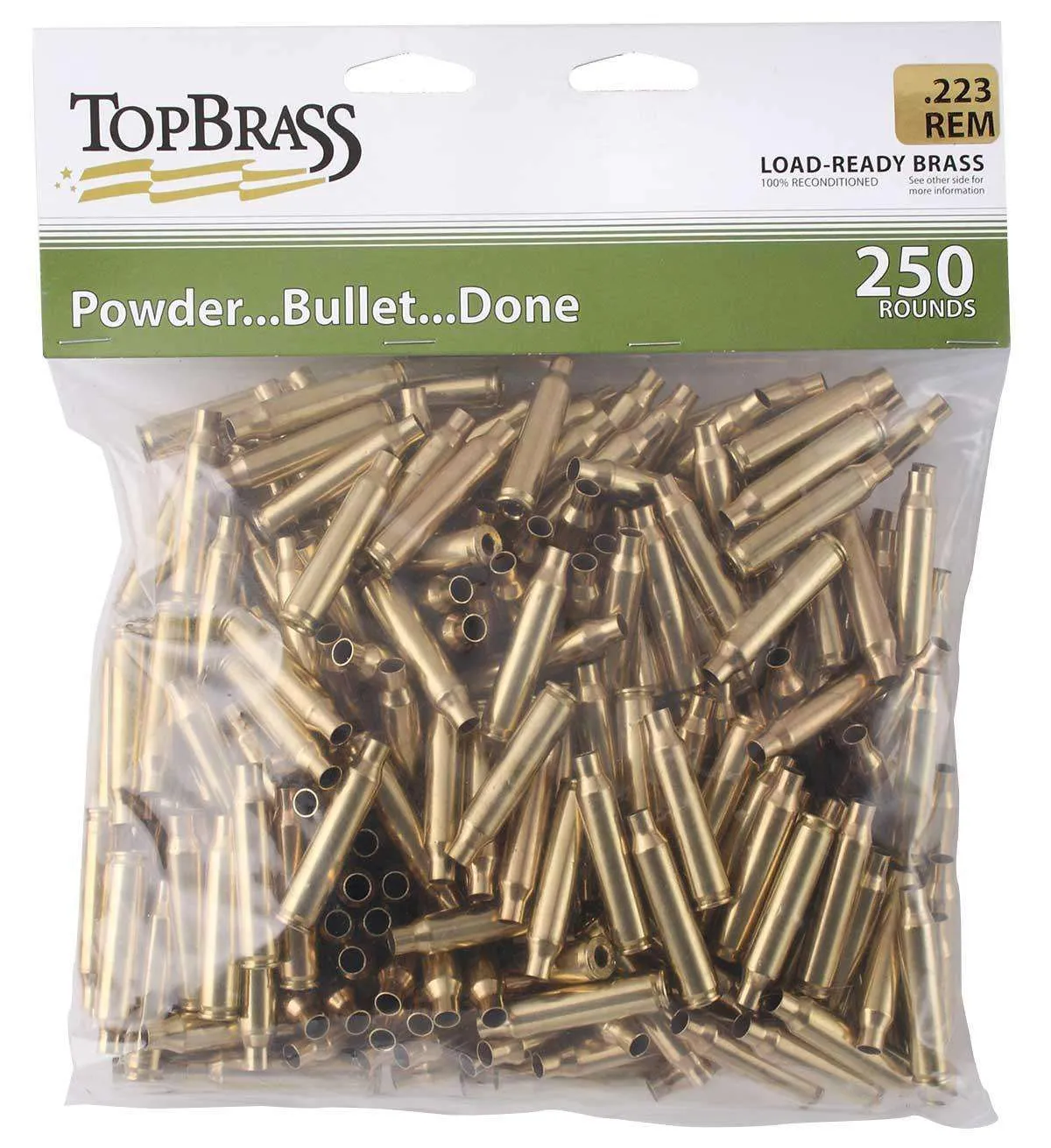

Top Brass 223 Rem Brass 250 Rounds

Top Brass is a leader in the brass industry, offering high-quality brass for reloading.

$56.25View DetailsIn Stock

-

15 % OFF

15 % OFF.223/5.56 - 55 Grain - 100 Rounds

55 grain 3050fps rounds, perfect for high-volume training and range practice.

$54.95 $65.00View DetailsIn Stock

Brass Selection Strategies for Optimal Performance

New vs. Once-Fired Brass

Reloaders face a critical decision between pristine new brass and carefully sourced once-fired cases. While new brass offers maximum consistency, high-quality once-fired brass from military or match-grade ammunition provides a cost-effective alternative without significant performance compromise.

Inspection Techniques

Rigorous brass inspection separates successful reloaders from amateurs. Implement these systematic evaluation methods:

- Utilize precision case gauges

- Check neck thickness with digital micrometers

- Examine primer pockets for wear

- Verify case length consistency

- Look for minimal signs of work hardening

Common Brass Selection Pitfalls

Avoiding these critical mistakes ensures superior reloading outcomes:

- Mixing Brass Brands: Avoid mixing different brass brands within the same loading batch, as this can lead to inconsistent performance.

- Using Damaged Brass: Do not use brass that shows signs of damage, such as dents, cracks, or stretched primer pockets, as these can lead to malfunctions.

- Overworking Brass: Refrain from excessive resizing, as this can weaken the case walls and reduce their lifespan.

- Using Brass with Significant Neck Wall Variations: Discard any brass that exhibits significant variations in neck wall thickness, as this can affect accuracy.

- Using Cases with Signs of Primer Pocket Expansion: Retire any cases that show signs of primer pocket expansion, as this indicates they may no longer be safe to use.

Technical Considerations for .223 Remington Brass

Reloading Cycle Limitations

Quality control studies have shown that proper defect analysis methods can help determine optimal reloading cycles:

- Match-grade brass: 5-7 reloading cycles

- Standard military brass: 3-4 reloading cycles

- Competition brass: Potentially 8-10 cycles with meticulous maintenance

How to Extend the Life of Your .223 Remington Brass

Annealing and Maintenance

Regular brass annealing extends case life, maintains elasticity, and prevents premature work hardening. Professional reloaders recommend annealing every 3-4 reloading cycles to preserve brass structural integrity.

Proper Storage

Keep brass in a cool, dry place to prevent corrosion. Check out our guide to storing ammunition for more information.

Moderate Loads

Avoid max loads to reduce stress on the brass. Consider using a reloading calculator to find the best load for your brass.

Investing in Quality Brass

While premium brass commands a higher initial investment, the long-term benefits far outweigh cost considerations.

Benefits of Choosing Premium Brass

- Enhanced accuracy

- Improved reliability

- More predictable shot-to-shot performance

- Extended case life

- Reduced potential for catastrophic failures

Evaluating Military Surplus Brass

Military surplus brass is a popular choice for budget-conscious reloaders. However, it often requires additional preparation:

- Crimp Removal: Military cases have crimped primer pockets that need to be removed.

- Inspection: Ensure no excessive wear or damage from previous use.

Tools and Techniques for Preparing .223 Rem Brass

To prepare brass for reloading, invest in these essential tools:

- Case Trimmer: Maintains uniform case length.

- Primer Pocket Cleaner: Removes debris for proper primer seating.

- Resizing Die: Restores brass to factory specifications.

Essential Reloading Equipment for 223/5.56

Success in reloading requires proper tools:

- Digital Reloading Scale: For precise powder measurements

- 223 Reloading Dies: Including sizing and seating dies

- Powder Dispenser: For consistent charge weights

- 223 Home Reloading Kit: All-in-one solution for beginners

Powder Selection and Data

When selecting powder for reloading 556x45 or 223 Remington:

- Consult current reloading manuals

- Reference Hornady 223 reloading data

- Consider Barnes reloading data for specific bullets

- Choose the best powder for your application (target, hunting, etc.)

Cost Analysis: Reloading vs. Factory Ammunition

Understanding the cost to reload 223 helps justify the investment:

- Brass: $0.30-0.75 per case (new)

- Primers: $0.08-0.12 each

- Powder: $0.15-0.25 per round

- Bullets: $0.20-0.40 each (55 grain to 62 grain)